Plastic has greatly altered the planet when it’s been introduced like a material to make things. Now you will find a large amount of helpful objects made from plastic plus they truly come handy for several situations. One industry which has greatly taken advantage of plastics may be the roofing industry using the great value that plastic roofing can offer when it comes to function and elegance.

Lightweight and occasional Cost

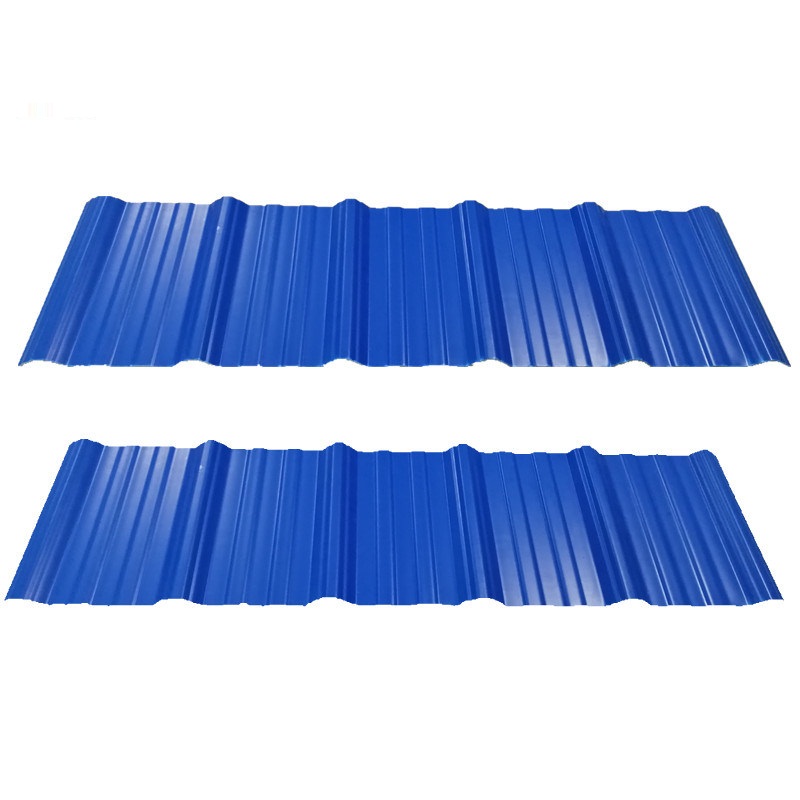

Using plastic in roofing has greatly elevated during the last couple of decades due to apparent and considerable benefits in comparison with other kinds of roofing materials for example metal, wood, slate, ceramic, and asphalt. What individuals like about plastic roofing is the lightweight, inexpensive, durability and easy installation. Plastic roofs are also available in different colors and therefore are extremely much attractive specifically for structures which have color motifs.

Ultraviolet Stabilizers

The primary drawback to plastic roofing is the possible sensitivity to light as well as heat. Plastic can melt or fade with much sun exposure and altering weather, however this problem can be handled using the thermal and ultraviolet stabilizers which have been put into newer productions of plastic roofs. Extreme climate conditions might take a toll around the usual plastic roofs but with the proper mixture of chemical components a number of plastic roofing material’s problems could be minimized.

Plastic Roofing is generally made from polycarbonate, a typical thermoplastic material we know of because of its excellent optical, thermal and mechanical features. The rooftop frequently is available in polycarbonate panels, sheets or tiles. What’s good concerning the polycarbonate materials are its good potential to deal with stress. It may withstand impact 200 occasions more than glass, and therefore it wouldn’t be prone to damage when gemstones or hail fall on the top. The mechanical qualities of this kind of roofing will also be rather resistant against alterations in temperature.

To strengthen the benefits of plastic roofing it’s possible to add ultraviolet radiation filters throughout the co-extrusion procedure for the sheet or even the panel. Special additives enables you to prevent excessive interior heating. Cavity structures also may help boost the load capacity and versatility of plastic roofing.

Lifetime Guarantee

Plastic roofing is available in different prices and quality with respect to the size, composition, thickness, colors, and profiles. The most typical plastic roofing profile that individuals see may be the corrugated one, because it has general better structural qualities than flat ones. The cheaper plastic roofs are constructed with PVC as the more costly and sturdier ones are constructed with polycarbonate components. The highest quality plastic roofs will come with lifetime guarantees.

Installing of plastic roofing isn’t very difficult, and that’s why it is almost always the roofing option for projects which have short time frames. For optimal installation ease, manufacturers frequently recommend installing plastic roofing on the roof with a minimum of 10 levels of pitching. Anything lesser than that could require extra weatherproofing measures for example adding flashings or sealants.

Cutting the plastic roof panels for resizing ought to be easily completed with an excellent toothed saw or a set of garden scissors. The greater the caliber of the plastic roof material, the simpler it’s to chop. Some installers use disk grinders with carborundum blades for additional precisions when cutting plastic roofs, although one sheet at any given time might be cut to prevent fusion and welding together.

Installation Tips

A great tip for installation is pre-drilling holes onto sheets prior to being installed. Holes usually ought to be from 8mm to 10mm with a few 2mm allowance in line with the screw shafts to permit contraction and expansion. Holes ought to be drilled around the greater area of the roof’s corrugation. It is almost always simpler to complete the drilling using the sheet on the floor, upside lower. A stick to an opening could also be used like a guide for drilling

Screws are utilized to secure the sheets of plastic roofing. Special screws are created for this function and could be easily purchased from plastic roof suppliers. The simplest screws to make use of are individuals with hexagonal heads. Most of the sheets or panels ought to be guaranteed with four corrugation spaces and also at every second when you will find overlaps, ridging, and gutters.

Plastic roofing is certainly commonplace choice in structural coverage. Using its great function, lightweight, and easy installation, it’s considered to stay a well known selection of roofing within the appropriate situations.